Tesla GigaFactory: the world’s largest manufacturer of lithium ion batteries

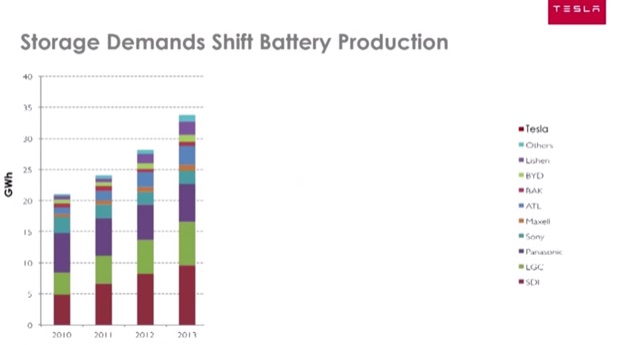

There’s one challenge with this though which is scaling up the entire production operation. We have enough space in our Tremont vehicle factory to build hundreds of thousands of vehicles. That factory when it was owned by Toyota years ago actually built almost that many vehicles so the world knows how to build a lot of vehicles. The bigger problem is where to get the batteries. This is an interesting graph of people can see it at all but these bars on the left are basically what happened with the world’s battery production over the last half a decade. It’s been growing fairly steadily. Almost all these batteries are made in Asia. The biggest battery players are Samsung, LG, Panasonic, Sony, those are the companies. And they are making batteries largely because they also made consumer electronics and they needed batteries for those products. It’s kind of a logical thing that they would have also gotten into the battery manufacturing business.

Storage Demains Shift Battery Production

Last year, Tesla was about 10% of that world battery market which is pretty phenomenal actually in and of itself. But it still sort of fits into overall structure of how this works. You know Panasonic is our largest battery provider and partner and we sold around 35,000 vehicles that year in 2014 and you can kind of see how that would work.

Now the problem is when we scale and continue ramping toward Model 3 and we get to somewhere about here. So looking forward to 2020 (now Tesla change this milestone to 2018) when we expect to be building and something about 500,000 vehicles per year. We need a round 35 GWH of energy storage per year just to feed into these vehicles.

Now that was more batteries in the whole world made in 2013. So this is a big problem and it was something that we’ve kind of seen coming several years in advance.

And while it’s also a big problem matching our supply chain and ramping up. We also saw this as a huge opportunity because instead of just building batteries the same way that they’ve been built for years and years for consumer electronics. We thought should there be a better way to do this when we want to build so many more of them. There must be a more efficient more cost effective way to do this when the market has grown by this much. So we had a vision to create a totally new type of factory, something that would be much more vertically integrated and something that would take a raw materials in one end and then go all the way through the process to completed battery packs at the other end.

This was kind of crazy idea in the beginning and we weren’t really sure exactly how this would come together. But ultimately this idea is what became the GigaFactory. And we worked for quite a few years before actually ending up here in Nevada on setting up partnerships and defining how this factory would operate internally and what would be the INs and OUTs. But at a high level this is going to be one of the biggest factories in the world, by far the biggest battery factory in the world. And we were able to achieve an economy of scale by doing that. They can drive the price down on energy storage much faster than people expected.

Instead of just buying incrementally more batteries made in the same way that consumer electronics are made from the same companies we’re deciding to build batteries close to where they’re needed, close to the vehicle production and close to where the sources of raw materials are going to be.

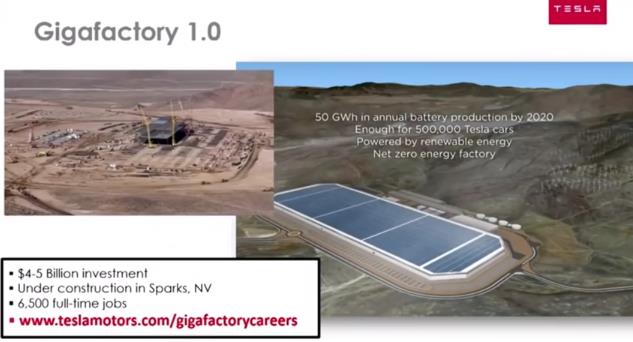

Gigafactory 1.0

So this factory will be able to build 500,000 cars per year. And have a total capacity of almost 50 GWH of full battery packs per year. We also had a vision to make this factory essentially net-zero energy and almost self-contained from an emissions and energy point of view. This is something that was very important to all of our customers. People buying Tesla vehicles are doing that because they care about sustainability, they care about the environment and they didn’t want us building batteries in a way that was damaging to the environment. That would seem sort of counterintuitive if they are buying a product that had a supply chain and manufacturing trail that create a lot of damage.

So again, we saw an opportunity to really embrace what customers care the most about, and also invent a factory that could have interesting new type of energy source and do this in a very unique way.

Today, we’re started construction just actually over a year ago. We started construction just east of sparks. This is a picture from when we shortly after we broke ground. We’ve continued building and I have to say hats off to the Nevada construction partners and trades that were working with. Construction here is moved extremely fast, that’s part of why we wanted to be in the battery first place but again, it’s exceeded our wildest expectations on how efficiently and how fast that we could actually build and implement here. And today the GigaFactory is still growing, still becoming a bigger and bigger site and we expect to have some of the first employees actually starting in the factory even in the next few weeks. And We will be building this facility out for years and years to come. But our strategy is to actually do operations and one-half even as we continue to expand and grow the other half of the factory.

We didn’t want to wait until everything was completed and then sort of have one giant opening instead we want to have a phased approach. But we can add employees and add production capability as we grow. I should also note that we’re hiring and it will show this link again but this is something that I think is really made community in the state are very excited and it’s actually happening. Here in the first time we’re beginning to hire a large numbers of people. We have several hundred people working on site now and more than 700 if you count construction and this will be ramping up steadily over the next few month and year to come.

So we really encourage anyone that interested in this to get in touch with us, look up what jobs are being offered. It’s a pretty diverse mix.

One other thing I should be mentioned is that you know we are so excited by all the enthusiasm that the whole community here has had for this project. It’s really pretty outrageous and some ways we’ve had any number of drone overflights and helicopter overflights and I’m sure everybody watched the drone’s videos on Youtube. Small airplanes in a photographer’s roaming hillsides and all of this. It is gotten a little bit out of control though and this is still incredibly active construction site. We have to take safety very seriously, both for our employees but also for people that happened to be in around the site. And I just want to caution everyone that you know especially if people are trying to sort of get a sneak peek at the site, you were happy to show anyone what’s going on. It is not secretive, nobody needs to sort of trespassing break-in to come and take a picture will be happy to show you.

Unfortunately just this last week, we had a bit of an incident with some photographers from the Reno desert journal that ended up putting some of our team members in a little bit of basically in a difficult situation for their own safety. So this is something that also is tough for us to have to manage. We treat the Tesla family like a family. We’re still pretty close-knit and very small and we want to be very welcoming and we want to have everyone doing and be a part of it. But we have to be really careful when things come to addressing our own team member safety.

So just to look at some of the different things that are hiring for this factory. This is a really diverse mix. I think a lot of people had maybe the misconception that this is only going to be some kind of giant labor pool of people assembling cells. This is actually going to be a much more diverse worker. We are building engineering and R&D teams are going to operate out of this factory. We already have engineering teams working out of the site under construction trailers. But they’re working there. And this is going to keep growing. So we’re hiring production engineers, manufacturing engineers, people that are helping design the control systems in the building itself, the energy systems, all the way through materials handling errors, human resources. This factory is going to have its own ecosystems of people that can run and maintain and support everything that’s going on there. It’s not going to be some satellite facility, that’s remotely controlled by some headquarters far away. This is a really key point and I think it’s critical to make it successful that it has that feel. It needs to feel like a startup in its own running.

The main mission for this GigaFactory has been also driving down the cost of storage, so something that may be taken for granted is this the amount of sort of effort that the world is put into energy storage today. It hasn’t really equaled what’s happening today. Today there’s more companies working on reducing the cost of batteries than ever there were before. And as we’re able to scale this up and we’re able to find ways to drop the price of storage much faster than anyone expected. We have this opportunity to do something that we’ve long thought was a bit of a missing piece. As said before all of our customers care deeply about sustainability. We founded the company to make sustainable transportation and electric vehicles are not completely sustainable unless the energy source that charges them is also sustainable. Perhaps that’s pretty obvious but it’s something that’s really important and we don’t want to have electric vehicles are powered from fossil fuels. We’d like to have them powered from renewable energy, solar or wind.

Unfortunately those solar and wind are of course intermittent. And the times when you want to charge your vehicle might not be the times when you have solar energy falling on your roof or on the middle of the desert if there’s a utility-scale planned. How Tesla storage clean, renewable and sustainable electricity? What is Tesla Energy? Click here to find out

Have you a channel youtube and want to bring your Video to quality visitors?

Do you want your video to appear on our website?

Do you want to become partner with us?

Just 3 steps to become our partner:

Step 1: Make video review for mods, addons, plugins, ... which you like

Step 2: Upload this video to youtube and our link to your video description

Step 3: Send the youtube video link via message to http://fb.com/9lifehack or leave a comment in the post. We will add your video in the our post, it will help you have more view.

JOIN to get more youtube view with us!!!!